Engineering Services

Problem Statement: Many factories face limitations with legacy hardware, closed-loop systems (Black Box), and disconnected data islands. Standard PLCs often struggle with complex algorithms, data retention, and modern IT integration.

The Challenge: Bridging the gap between OT (Operational Technology) and IT (Information Technology) requires deep expertise in both machinery and software architecture. Upgrading systems without disrupting production is critical.

Our Core Solutions

We operate as a specialized System Integrator (SI) focusing on PC-Based Control and Industrial Software Architecture.

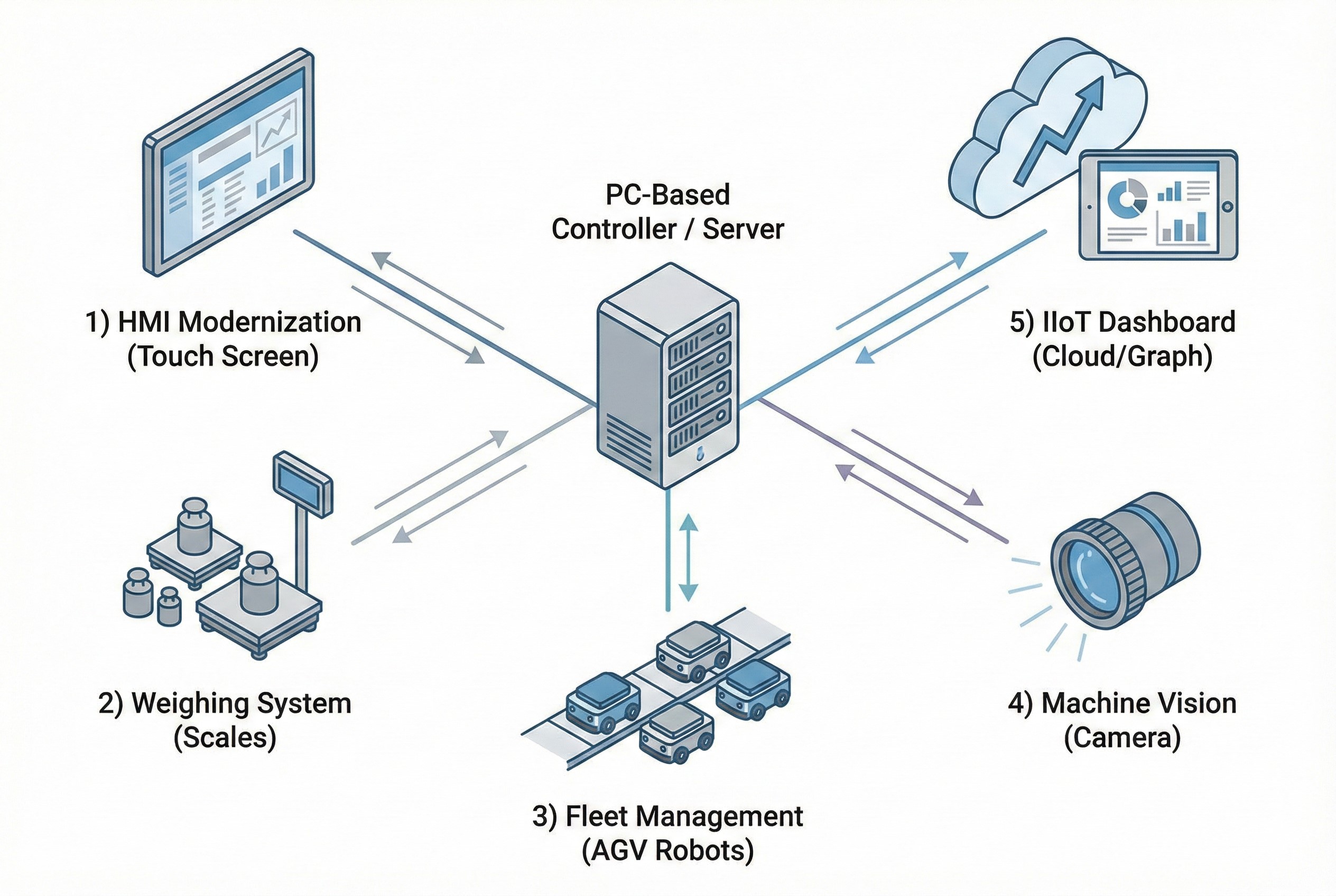

1. Machine Control & HMI Modernization

We unlock the potential of legacy machines by replacing outdated hardware with flexible PC-Based solutions.

- HMI Retrofit: Replace obsolete screens (e.g., UniOP) with C# (.NET/WPF) applications running on Industrial PCs. This allows for unlimited recipe storage and easier database connectivity.

- Complex Motion Control: Implement advanced algorithms, such as converting XYZ coordinates to LRA motor movements for Tube Auto Bending Machines or controlling Banbury Mixers with precision.

2. Process Control & Pokayoke Systems

Eliminate human error in critical production processes using software-driven logic.

- Chemical Weighing & Formula Control: Systems that enforce strict recipe adherence by interlocking with digital scales and PLCs. If the weight is incorrect, the process stops immediately.

- Traceability: Real-time material stock cutting and barcode scanning to ensure every lot is trackable.

3. AGV/AMR Fleet Management

We build the “Brain” for autonomous logistics.

- Traffic Control System: A centralized server managing multiple AGVs/AMRs to prevent collisions, manage queues, and optimize routes using Path Finding Algorithms.

- Wireless Connectivity: Command robots via MQTT Protocol over Wi-Fi for real-time task assignment in dynamic environments.

4. Machine Vision Inspection

Automated Quality Assurance (QA) replacing manual visual checks.

- Visual Inspection: Defect detection on metal parts or complex geometries using industrial cameras.

- High-Speed OCR & Barcode: Verifying product labels and reading codes on high-speed production lines to prevent mismatched products.

5. Data Logging & Industrial IoT

Connecting the factory floor to the boardroom.

- Data Acquisition: Extracting data from PLCs, Digital Meters, and CNCs to central servers.

- Real-time Monitoring: Web-based Dashboards (developed with Node-RED, Vue.js) for monitoring OEE, energy consumption (e.g., Crepper Motor Monitoring), and production status accessible from anywhere.

Ready to modernize your factory? Contact us at: wisit.paewkratok@gmail.com