CSIAPipeBender: High-Precision Tube Bending Controller

Problem Statement: In traditional tube bending, operators often struggle with complex geometry calculations. converting a 3D drawing (XYZ coordinates) into machine actions (Length, Rotation, Angle) requires advanced mathematics. Additionally, physical factors like Spring Back (metal elasticity) and Elongation (stretching) often lead to inaccurate bends, requiring significant trial and error.

The Challenge:

- Complex Math: Manual calculation of bend sequences is prone to human error.

- Material Behavior: Different tube materials react differently; a standard fixed program cannot account for spring back variance without a smart compensation algorithm.

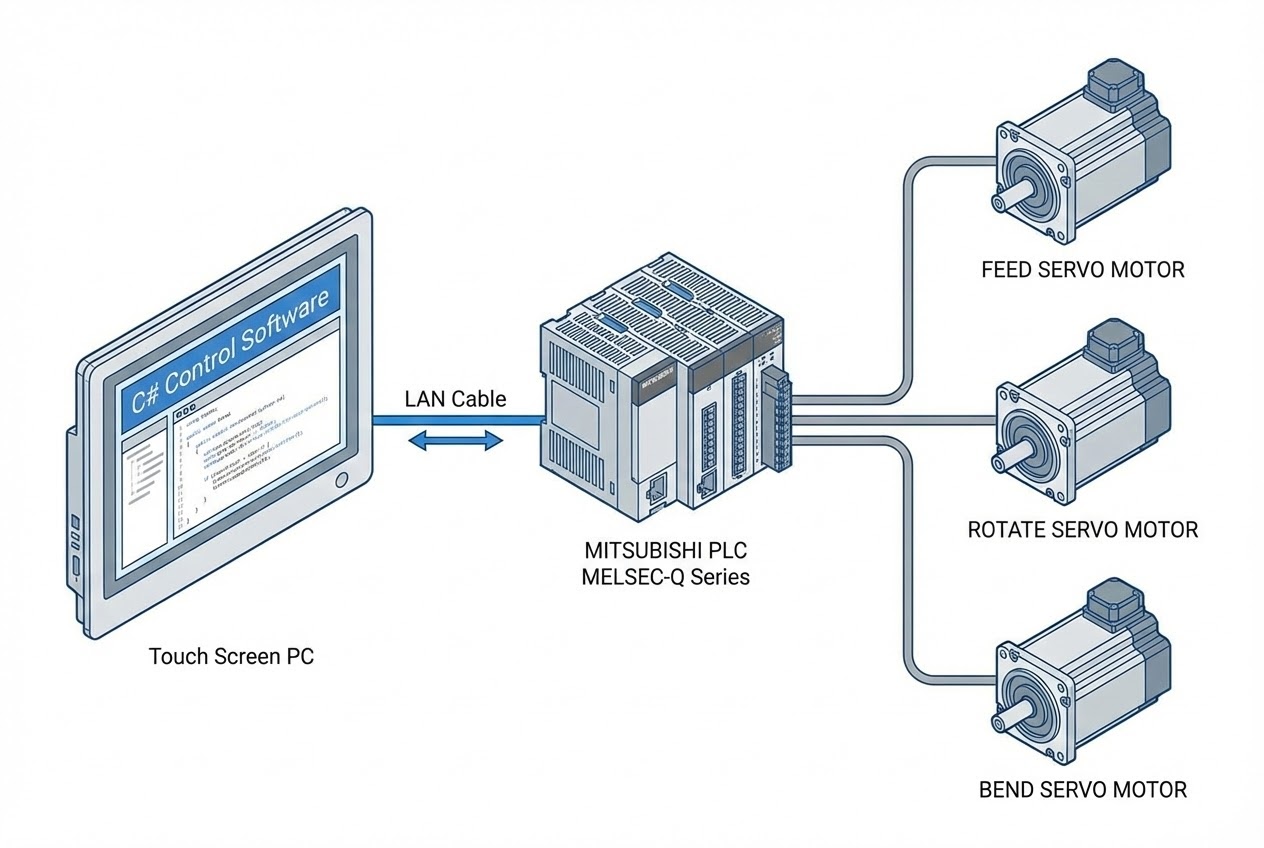

Our Solution: PC-Based CNC Architecture

We developed CSIAPipeBender, a Windows-based HMI/Controller that acts as the “Brain” for the machine, while the Mitsubishi PLC acts as the “Muscle.”

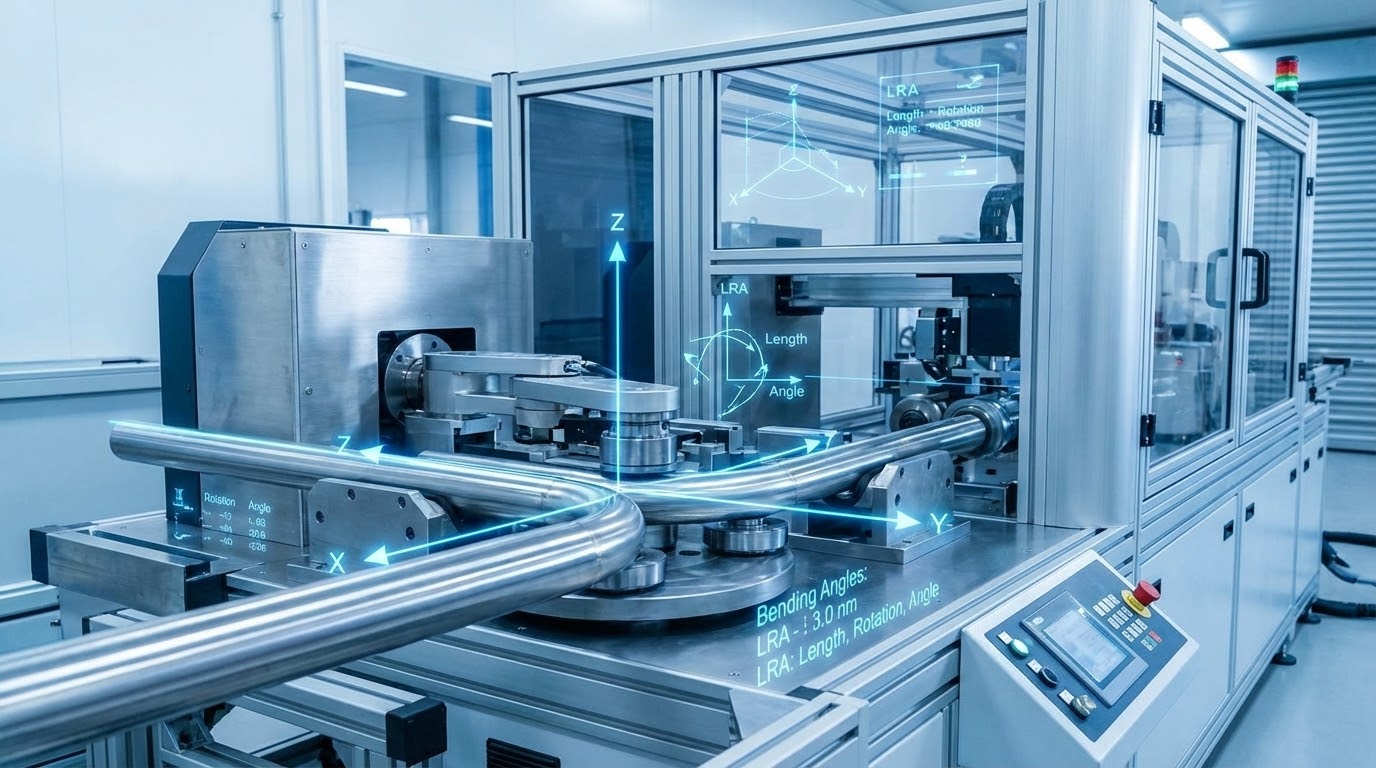

Core Logic: XYZ to LRA Conversion

The heart of this system is a custom algorithm that allows operators to input coordinates directly from the blueprint.

- Input: User enters 3D Coordinates (X, Y, Z).

- Process: The C# Application calculates the vector transformation to derive:

- L (Length): Feeding distance.

- R (Rotation): Orientation of the tube.

- A (Angle): The actual bend angle.

- Compensation: The system automatically applies offsets for Spring Back and Elongation based on material properties before sending commands to the PLC.

Hardware & Integration

- Controller: Mitsubishi MELSEC iQ-R Series (R04CPU/R08CPU) – A high-performance PLC for rapid execution.

- Motion Control: RD75 Positioning Module controlling 3 Axis Servo Motors (Feed, Rotate, Bend).

- Connectivity: The PC communicates with the PLC via Mitsubishi MX Component (Ethernet/USB), ensuring reliable high-speed data exchange.

Key Technologies Implemented

| Technology | Role in System |

|---|---|

| C# (.NET WinForms) | User Interface, Mathematical Engine, and Recipe Management (SQLite). |

| Mitsubishi MX Component | Middleware for PC-to-PLC communication. |

| SQLite | Local database for storing unlimited bending recipes. |

Business Results

- Simplified Operation: Operators no longer need to be mathematicians. Input XYZ, and the machine does the rest.

- High Precision: Automated compensation reduces waste materials from trial bends.

- Scalability: The Recipe Management system supports unlimited part programs, ideal for high-mix, low-volume production.

Expert Insight: Moving complex calculations (like XYZ-to-LRA) from the PLC to a PC (C#) allows for more sophisticated algorithms and a better UI, while keeping the PLC focused on what it does best: critical real-time motion control.

Looking for a Custom CNC Solution? Contact us at: wisit.paewkratok@gmail.com