High-Precision Sliding Tester Control System

Problem Statement: The client, a leading automotive parts manufacturer, relied on a manual or semi-manual process for endurance testing (cyclic motion) of their products. The existing control software was built on legacy technology (WinForms), making it difficult to maintain, prone to human error in parameter settings, and lacked the flexibility to adapt to new hardware sensors.

The Challenge:

- Human Variation: Manual setups led to inconsistent test results (speed, acceleration, cycle counts).

- Legacy Debt: The old codebase was tightly coupled with specific hardware drivers, meaning replacing a broken motor or sensor required a complete software rewrite.

- Reliability: The system needed to run thousands of cycles continuously without crashing or losing data.

Our Solution: Clean Architecture for Industrial QC

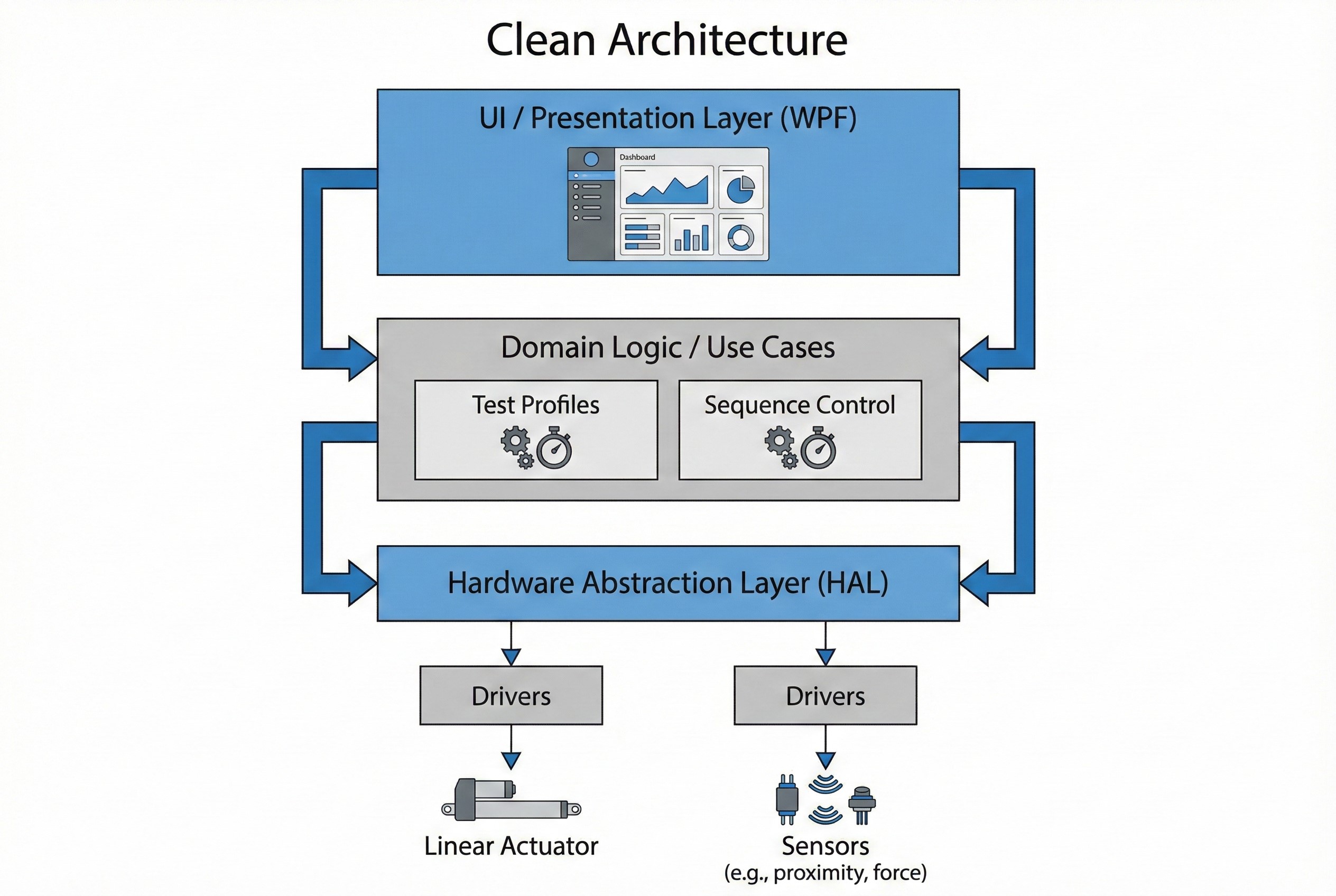

We re-engineered the entire control system using Modern C# (WPF) and adopted Clean Architecture principles. The focus shifted from simple “control” to creating a robust “platform” for quality assurance.

Key Technologies Implemented

| Technology | Role in System |

|---|---|

| C# (.NET / WPF) | Modern, responsive UI with real-time data binding for smooth monitoring. |

| Clean Architecture | Decoupled business logic from hardware, ensuring long-term maintainability. |

| Hardware Abstraction Layer (HAL) | Allows swapping actuator brands or sensors without changing the core software logic. |

| Motion Control Algorithms | Precise control of Move Absolute, Jog, and Acceleration profiles. |

System Highlights

- Automated Cycle Control: Users can set complex test loops (e.g., 20,000 cycles) and let the system run autonomously.

- Profile Management: Standardized “Test Profiles” ensure that Speed, Distance, and Acceleration are identical every time, regardless of the operator.

- Real-time Monitoring: The dashboard visualizes Actuator Position and Digital I/O status instantly, allowing engineers to verify behavior without standing at the machine.

Business Results

- 100% Data Integrity: Eliminated human error in test parameter configuration.

- Hardware Agnostic: Reduced future maintenance costs by allowing easy hardware replacement via the HAL.

- Operational Efficiency: QC engineers can monitor multiple tests remotely via the refined UI, reducing idle time.

Expert Insight: In QC automation, Repeatability is King. By refactoring to a Hardware Abstraction Layer, we not only improved current stability but also “future-proofed” the machine against hardware obsolescence.

Need to modernize your QC equipment? Contact us at: wisit.paewkratok@gmail.com