Rubber Compounding & Precision Weighing Control System

Problem Statement: In the Master Batch (MB) and Carbon Master Batch (CMB) production lines of a leading automotive rubber manufacturer, manual chemical weighing processes were prone to human error. Deviations from the specific rubber formula resulted in quality issues, waste, and a lack of digital traceability.

The Challenge:

- Precision Requirement: The system must interface directly with high-precision scales to ensure chemical weights fall within strict tolerance levels.

- Network Instability: Production cannot stop even if the factory network/server goes down.

- Inventory Control: Need real-time stock deduction and validation to prevent incorrect material usage (wrong lot/wrong type).

Our Solution: Smart Weighing & Interlock System

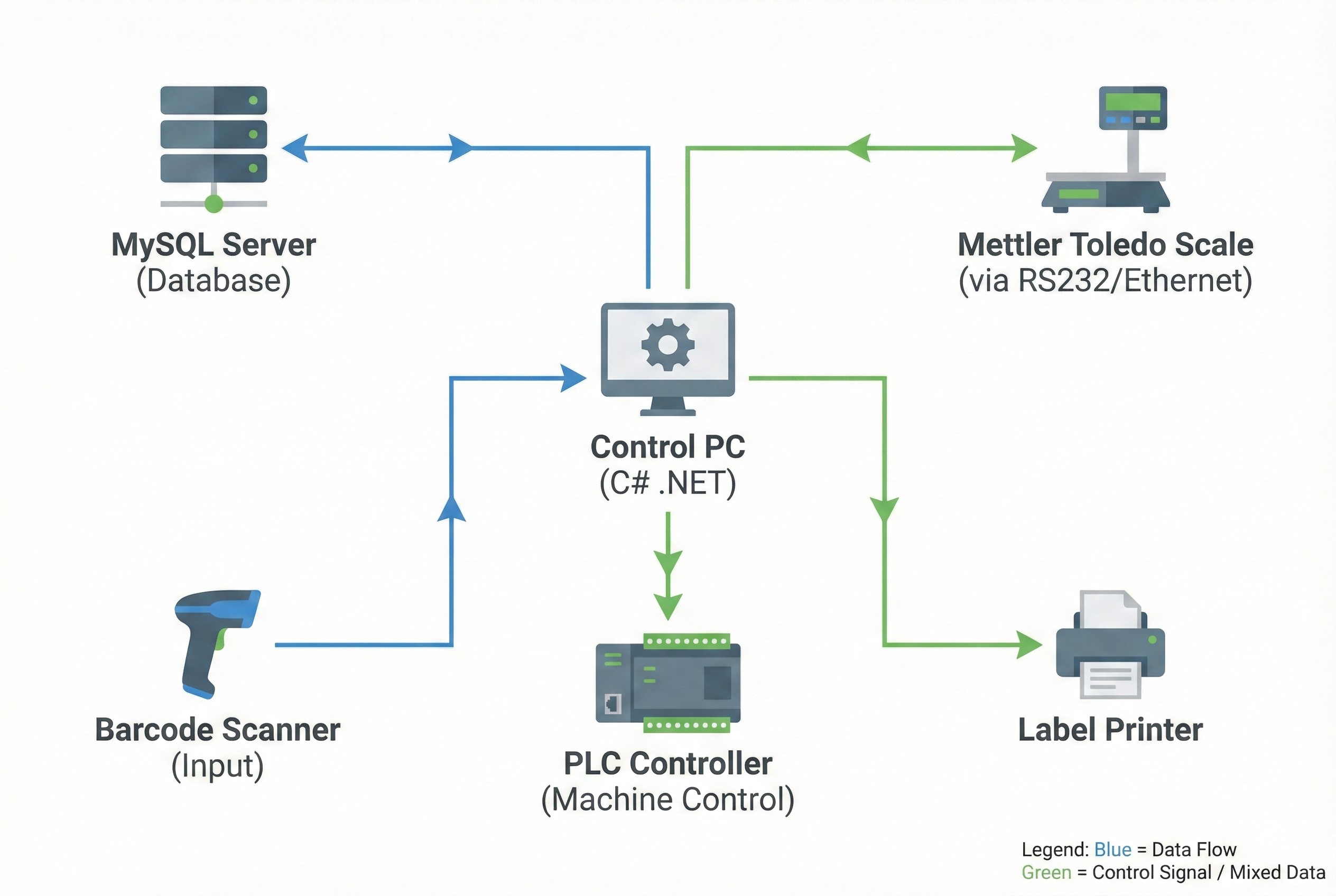

We developed a robust Windows Forms Application (C# .NET) that acts as the “Process Controller” for the mixing line. The system integrates IT and OT layers to enforce strict process control.

Key Features

- Formula & Plan Management: Retrieves production plans from the central MySQL Server. The system strictly locks the machine; operators cannot proceed if the raw material weight or type does not match the formula.

- Hybrid Database Architecture (Offline Mode): A critical feature for reliability. The system caches data locally using SQLite. If the network fails, the production line continues seamlessly, syncing data back to the Master DB once connectivity is restored.

- Hardware Interlock:

- Mettler Toledo Integration: Real-time weight reading (IND890).

- PLC Handshake: The software sends “OK/NG” signals to the PLC to allow or block the mixing process.

Key Technologies Implemented

| Technology | Role in System |

|---|---|

| C# .NET (WinForms) | Main control application and user interface |

| MySQL | Centralized Master Database (Formula, Plan, Stock) |

| SQLite | Local Backup Database for offline resilience |

| Mettler Toledo | High-precision weighing scale integration |

| PLC Integration | Machine control and status monitoring |

Business Results

- 100% Traceability: Every batch produced is tracked with exact chemical weights, lot numbers, and timestamps.

- Zero Formula Error: The system physically prevents adding incorrect materials or wrong weights via PLC interlocks.

- High Availability: The Local Caching (SQLite) feature eliminated downtime caused by network fluctuations.

Expert Insight: In critical production lines like Rubber Compounding, never rely solely on a central server. Implementing a “Local First” architecture with SQLite ensures that the factory keeps running even when the IT infrastructure faces issues.

Looking to optimize your batch production? Contact us at: wisit.paewkratok@gmail.com