Mass Production Aging Test System

Problem Statement: The client required a mass production testing facility for MXR100030 (30kW) and MXR100050 (50kW) charging modules. The scale involves testing 20 units simultaneously per workstation.

The Challenge: The 10-Second Deadline The most critical engineering constraint is the module’s internal Watchdog Timer.

- If a module does not receive a valid communication packet within 10 seconds, it automatically cuts off the DC power output.

- With 20 devices flooding the bus with telemetry data, network congestion could easily cause a “Heartbeat Miss,” leading to a failed test and production downtime.

Our Solution: High-Throughput CAN Architecture

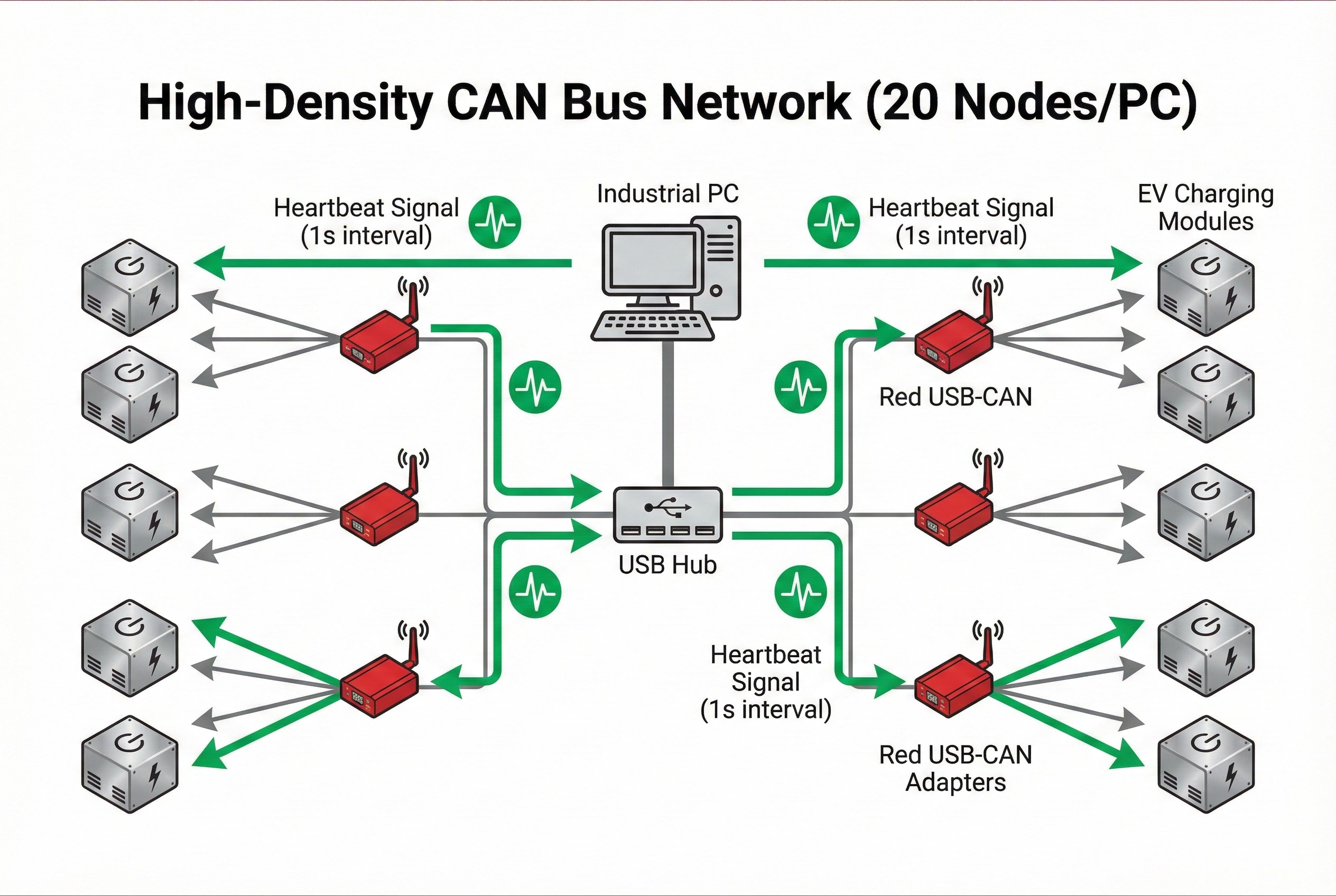

We designed a Multi-Threaded Control Application capable of handling high-density traffic without latency. We moved away from a single daisy-chain loop to a Tree Topology using USB-CAN Hubs to distribute the bandwidth load.

Network Topology Strategy

Instead of overloading a single CAN channel, we utilized a USB Hub -> Multiple USB-CAN Adapters architecture (as seen in the project schematic).

- Load Balancing: Splitting 20 units across multiple CAN channels prevents bus saturation.

- Asynchronous Heartbeat: A dedicated background thread (“Keep-Alive Service”) ensures every unit receives its command packet within the 10s window, regardless of the UI’s processing load.

Key Technologies Implemented

| Technology | Role in System |

|---|---|

| C# (TPL & Async/Await) | Handling 20 concurrent state machines without UI freezing |

| Priority Queueing | Ensuring “Keep-Alive” packets have higher priority than logging data |

| USB-CAN Aggregation | Managing multiple COM ports as a single logical network |

Business Results

- Zero Downtime: Eliminated false-positive cut-offs caused by communication timeouts.

- Scalability: The system successfully manages 20 units of MXR100030 per PC with stable millisecond-level response times.

- Real-time Visibility: Operators can monitor voltage/current of all 20 units on a single dashboard.

Expert Insight: When controlling hardware with a strict Watchdog (like the 10s cutoff here), never rely on the main UI thread for communication. We implemented a “Fire-and-Forget” UDP-style logic strictly for the Keep-Alive signal to guarantee the modules stay active.

Facing latency issues in your industrial network? Contact us at: wisit.paewkratok@gmail.com