Adaptive Visual Inspection for Stamped Parts

Problem Statement: In automotive part manufacturing, “Stamped Characters” (serial numbers/codes) are critical for traceability. However, the physical stamping process is inconsistent. Factors like die wear, hydraulic pressure changes, or slight positioning shifts cause the characters to look different over time.

The Challenge: A traditional Vision System uses a static “Master Image.” When the production line’s stamping tool degrades slightly, the characters no longer match the static Master perfectly. This leads to a high rate of False Rejects (Good parts being rejected), causing frequent machine downtime and requiring constant code adjustments by engineers.

Our Solution: Dynamic Template Management

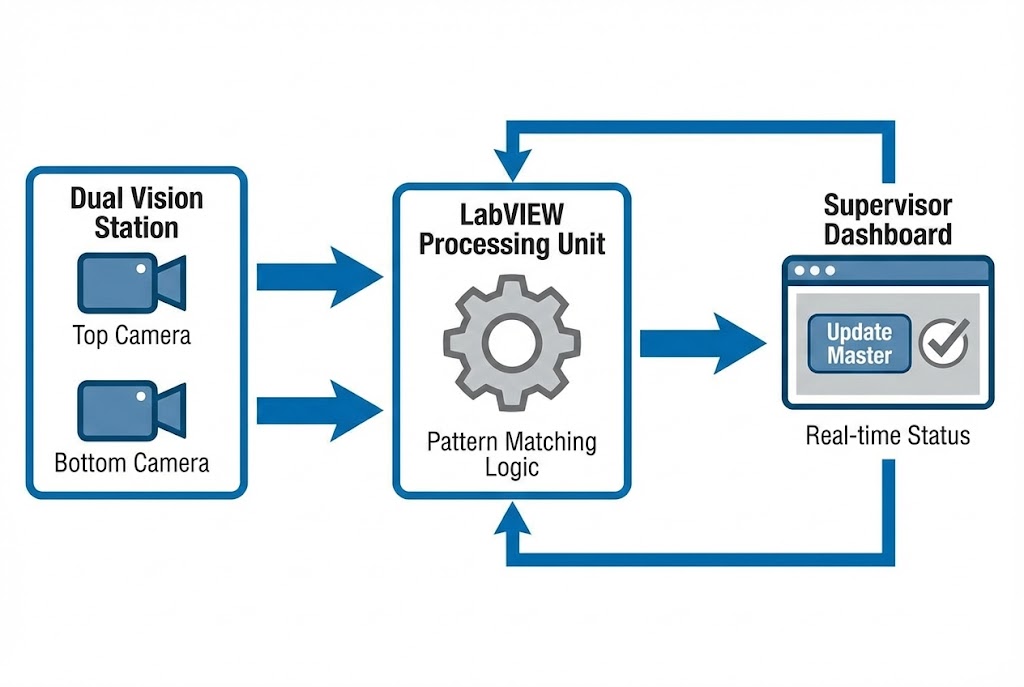

We developed a Visual Inspection Machine using LabVIEW and NI Vision Module with a specialized feature: “Supervisor Calibration Mode.”

This feature empowers line supervisors to manually update the “Master Template” and adjust matching thresholds directly via the UI, without needing a programmer or stopping the line for extended periods.

Key Features

- Dual View Inspection: Two cameras simultaneously inspect the Top and Bottom of the part to ensure 100% coverage.

- User-Defined Master: A dedicated “Calibrate & Setting” menu allows the supervisor to capture a current “Good Sample” and set it as the new Master Template instantly.

- Real-time Scoring: The system displays a similarity score (0-1000). If the score trends downwards due to tool wear, the supervisor can proactively update the Master before failures occur.

Key Technologies Implemented

| Technology | Role in System |

|---|---|

| LabVIEW | Main Vision Processing Software & UI |

| NI Vision Pattern Matching | Core algorithm for character verification |

| Arduino Controller | Low-cost I/O interface for Pneumatic Jigs & Tower Lamps |

| State Machine Architecture | Managing complex sequences (Move In -> Snap -> Process -> Move Out) |

Business Results

- Reduced Downtime: Supervisors can resolve “False Reject” issues in under 1 minute by updating the Master.

- Cost Efficiency: Using an Arduino-based controller for I/O significantly reduced the hardware cost compared to industrial PLCs.

- Flexibility: The system accommodates natural variations in the manufacturing process without compromising quality standards.

Expert Insight: In Vision Systems involving metal stamping, “Lighting” is 50% of the solution. We used controlled LED lighting (Top/Bottom) triggering via Relay to create high-contrast images, minimizing the effect of ambient light reflections on the metal surface.

Struggling with false rejects in your Vision System? Contact us at: wisit.paewkratok@gmail.com