Precision Agriculture for Commercial Hemp

Problem Statement: Hemp (Cannabis sativa) is a highly sensitive crop. Successful cultivation requires precise control over the Vapor Pressure Deficit (VPD). Excessive humidity leads to mold (Bud Rot), while improper lighting schedules can disrupt the flowering cycle. Managing 8 large-scale greenhouses manually is inefficient and risky.

The Challenge: The project required retrofitting and automating 4 out of 8 greenhouses. The system needed to integrate various actuators (Fans, Curtains, Pumps) and execute complex logic based on multiple sensor inputs (Light, Temp, Humidity) and Schedules.

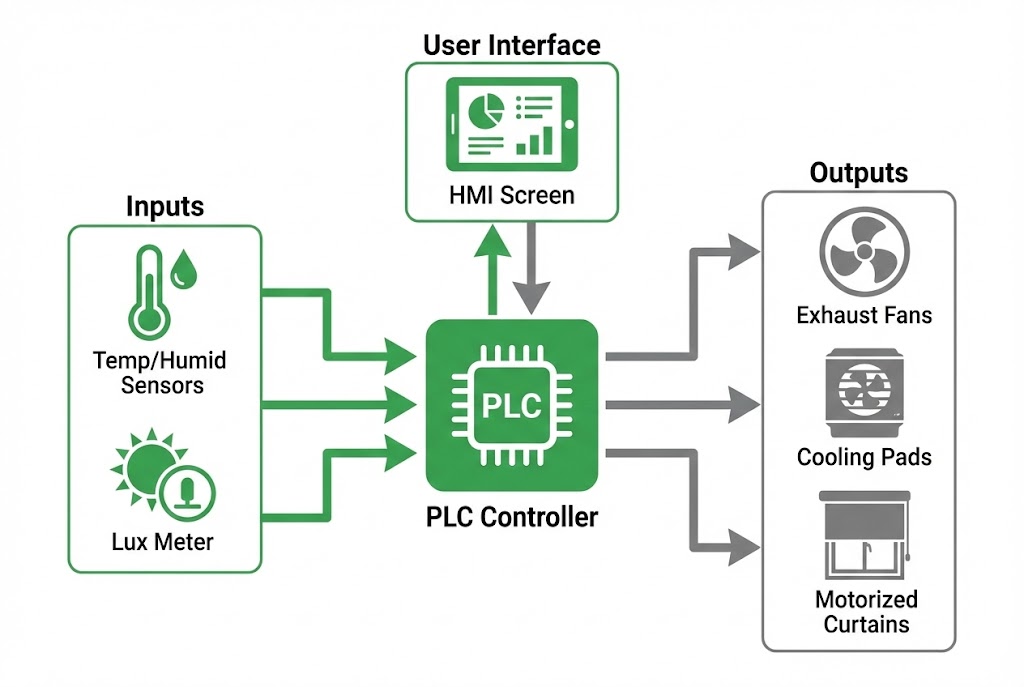

Our Solution: PLC-Based Environmental Control

We designed a robust automation system using Industrial PLCs coupled with an intuitive Touchscreen HMI. The system acts as the “Brain” of the greenhouse, making real-time decisions to maintain the ideal microclimate.

Key Control Logic

- Smart Cooling System:

- Step Control: Automatically stages 50" Exhaust Fans and Gable Fans based on heat load.

- Mold Prevention: The Evaporative Cooling Pad (Evap) pump automatically cuts off if humidity exceeds safety thresholds, preventing fungal growth during the flowering stage.

- Automated Lighting (Photoperiodism):

- Shading Curtains: Automatically deploy based on Lux Meter readings to prevent light stress.

- Blackout System: Timer-based control for “Side Blackout” curtains to strictly enforce 12/12 flowering light cycles.

- Circulation:

- Leaf Blowing Fans: Programmable timers to ensure consistent airflow within the canopy, reducing micro-climates.

Key Technologies Implemented

| Technology | Role in System |

|---|---|

| PLC (Programmable Logic Controller) | Core logic processing and hardware interfacing |

| HMI (Human Machine Interface) | Central monitoring dashboard and parameter adjustment |

| Analog Sensors (4-20mA) | Precision Temperature, Humidity, and Light intensity reading |

Business Results

- Crop Protection: Significantly reduced the risk of mold and mildew through automated humidity limits.

- Consistency: Achieved uniform growth across all 4 automated units due to synchronized environmental control.

- Labor Reduction: Eliminated the need for manual curtain and fan operation, allowing staff to focus on plant care.

Expert Insight: For hemp farming, “Sensor Calibration” is critical. Our software includes an Offset Function, allowing growers to calibrate system sensors against handheld reference devices to ensure absolute accuracy.

Looking to upgrade your farm to a Smart Farm? Contact us at: wisit.paewkratok@gmail.com