Gearset Matching Data Collection System

Problem Statement: A Tier-1 automotive manufacturer in Pluak Daeng, Rayong, faced a traceability challenge with their Oerlikon T60 (Bevel Gear Testing) machines. The machine performs critical matching tests for Ring and Pinion gears, but the test results were stored locally in proprietary text files.

The Challenge:

- Closed System: The machine runs on legacy software. Modifying the internal code to send data to a database was deemed too risky and would void the manufacturer’s warranty.

- Data Silo: Quality engineers had to manually check files, leading to data gaps and lack of real-time traceability in the central ERP/MES.

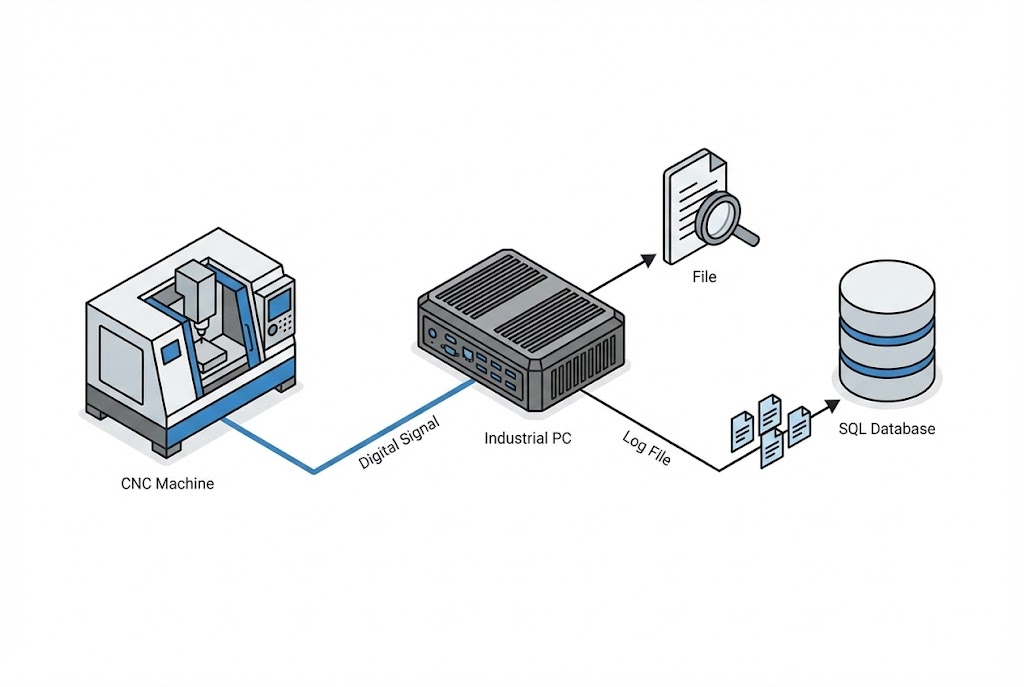

Our Solution: The “Sidecar” Integration Pattern

We implemented a Non-Intrusive Data Collection System. Instead of hacking the machine’s software, we treated the machine as a “Black Box” and monitored its outputs externally.

How It Works (Step-by-Step)

- Identity Verification: The operator scans the Barcode/QR Code of the Ring and Pinion gears using a handheld scanner connected to our custom Industrial PC (IPC).

- Validation: Our system checks the MSSQL Server to ensure these parts have passed previous processes (Op-Check).

- Testing & Triggering: The Oerlikon T60 runs its standard test cycle.

- Key Technique: We installed a DAQ Card (Data Acquisition) to intercept the machine’s “Test Complete” signal (24V I/O) physically.

- Data Extraction: Once the DAQ receives the signal, our software:

- Maps the network drive to the machine’s path (

\\xxx\TEST_xxxx\Protocols\*.prt). - Locates the latest generated Log file (

.prt). - Parses the text file to extract specific parameters (Backlash, noise levels, contact patterns).

- Maps the network drive to the machine’s path (

- Data Archiving: The extracted data is paired with the scanned Serial Numbers and saved directly to the central MSSQL Server.

Key Technologies Implemented

| Technology | Role in System |

|---|---|

| C# (.NET WPF) | Main application for UI, logic, and file parsing. |

| DAQ (IO Card) | Hardware trigger to synchronize data reading with machine cycle. |

| File I/O Parsing | Logic to read and extract data from unstructured legacy log files (.prt). |

| MSSQL Server | Centralized storage for traceability and integration with upper systems. |

Business Results

- 100% Traceability: Every gear set produced is now automatically logged with its quality parameters.

- Zero Downtime Risk: Because we didn’t touch the Oerlikon’s internal software, the production line remained stable with no risk of software corruption.

- Automated Workflow: Eliminated manual data entry, reducing human error to 0%.

Expert Insight: When dealing with expensive, proprietary machinery (like CNCs or Testers), avoid modifying the internal PLC/PC logic if possible. Using an external “Listener” approach (monitoring Files, I/O signals, or screen scraping) is often safer, faster, and cheaper.

Need to extract data from your legacy machines? Contact us at: wisit.paewkratok@gmail.com