Visualizing Invisible Energy Costs

Problem Statement: In large-scale manufacturing, electricity bills are a major operating cost, yet they often remain a “Black Box.” Factory managers struggle with manual meter readings, lack of real-time visibility into power consumption trends, and inability to correlate energy spikes with specific production processes.

The Challenge: The client needed a centralized system to collect data from multiple Digital Multimeters distributed across the factory. The system had to handle high-frequency data (Voltage, Current, Power, THD), process it for cost analysis, and present it on a responsive web dashboard accessible from anywhere.

Our Solution: Event-Driven IoT Platform

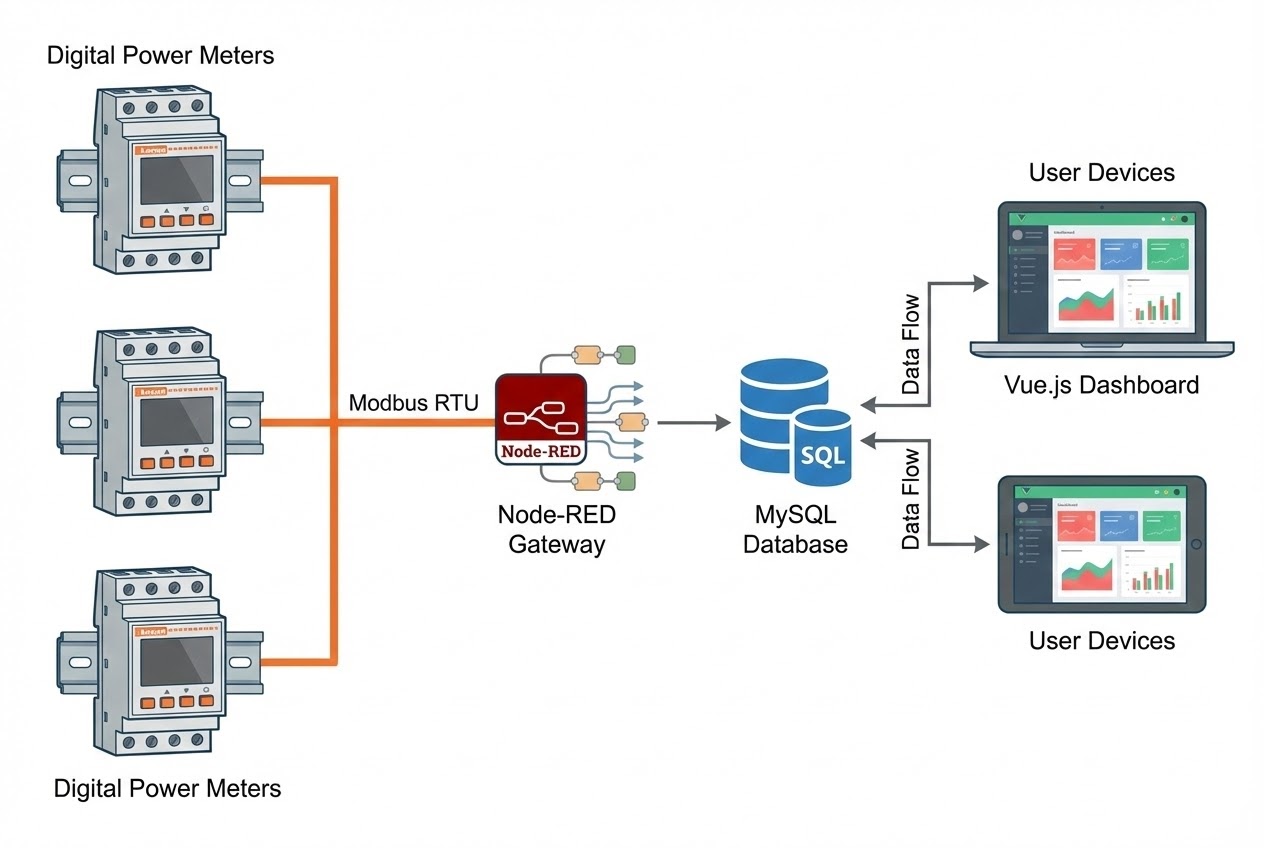

We architected “Factory Insight,” a robust monitoring solution built on the Node-RED ecosystem for reliable data acquisition and Vue.js (Quasar Framework) for a high-performance frontend user interface.

Key Features

- Real-time Telemetry: Live monitoring of electrical parameters including Voltage (V), Current (A), Power (kW), Power Factor, and Frequency (Hz).

- Power Quality Analysis: Monitors Total Harmonic Distortion (THD) to detect “Dirty Power” that could damage sensitive machinery.

- Cost Intelligence: Automatically calculates estimated electricity costs ($/THB) based on consumption, helping in budget forecasting.

- Advanced Reporting: Generates Daily, Weekly, and Monthly energy reports with “Export to Excel/CSV” functionality for further audit.

Key Technologies Implemented

| Technology | Role in System |

|---|---|

| Vue.js 3 (Quasar) | Responsive & Fast Frontend Dashboard |

| Node-RED | IoT Gateway, Data Aggregation, and API Backend |

| MySQL | Historical Data Storage |

| Modbus RTU | Communication protocol with Power Meters |

Business Results

- Data Integrity: Implemented “Gap Filling” logic (

aggregateBackfillSequential.js) to ensure continuous data streams even during network hiccups. - Operational Efficiency: Replaced manual logbooks with automated digital reports, saving hours of engineering time per week.

- Predictive Maintenance: THD monitoring allows early detection of motor or drive anomalies before failure occurs.

Expert Insight: Reliability is key in data logging. We utilized Node-RED not just as a smart aggregator that pre-processes raw Modbus data into hourly and daily summaries, significantly reducing the query load on the MySQL database for long-term reporting.

Ready to optimize your factory’s energy usage? Contact us at: wisit.paewkratok@gmail.com