Real-time Crepper Motor Monitoring System

Problem Statement: In a large-scale rubber processing plant, the “Crepper Machines” are the heart of production. The client, Sri Trang Agro-Industry PCL, needed to monitor the electrical current (Amps) of 3 critical motors in real-time. Previously, operators had to manually check readings from local panel meters, making it impossible to analyze historical trends or detect anomalies (like motor overload) instantly.

The Challenge:

- Legacy Connectivity: The existing meters were standard Digital Meters (Primus TCM-94N-AB) communicating via Modbus RTU over RS-485, requiring a reliable bridge to the IT network.

- Data Integrity: The system needed to handle potential connection drops and ensure data continuity for accurate reporting.

- User Accessibility: The dashboard had to be accessible via a web browser on the local network without complex software installation on client machines.

Our Solution: Hybrid IoT Gateway

WP Solution architected a Web-based Monitoring System that bridges the gap between the factory floor and the control room. We utilized Node-RED as a robust middleware to poll data from the meters and Vue.js for a high-performance frontend dashboard.

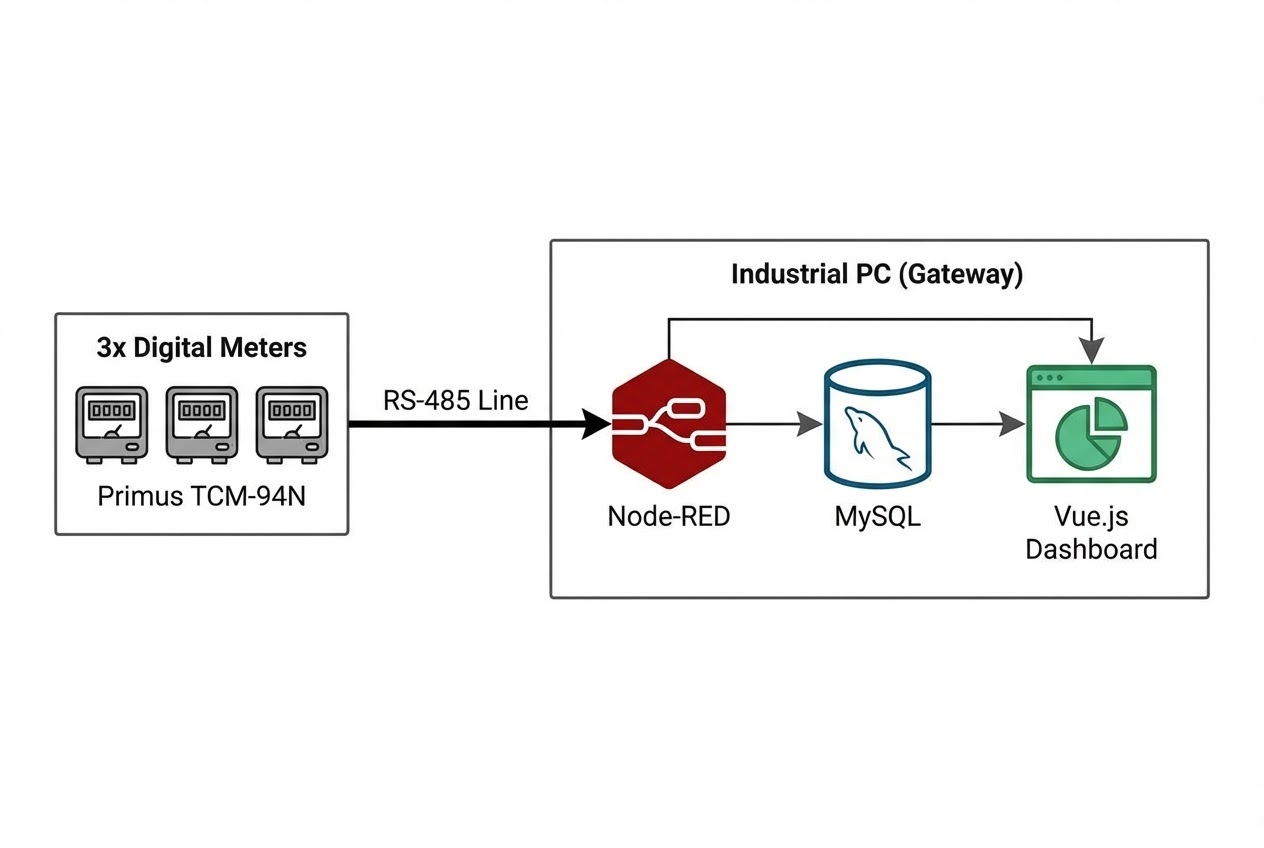

System Workflow

- Data Acquisition: An Industrial PC connects to 3 Digital Meters via RS-485 (Modbus RTU).

- Processing (Node-RED): Node-RED polls current, voltage, and power data every second, processing and filtering signal noise.

- Storage (MySQL): Processed data is logged into a MySQL Database (V8.x) for long-term historical analysis.

- Visualization (Vue.js): A responsive web dashboard displays real-time gauges and historical line charts, allowing engineers to track motor health instantly.

Key Technologies Implemented

| Technology | Role in System |

|---|---|

| Node-RED | IoT Gateway & Logic Controller (Low-code backend) |

| Vue.js | Reactive Frontend Framework for smooth Dashboard UI |

| MySQL | Relational Database for storing historical motor data |

| Modbus RTU | Industrial Protocol for communicating with Digital Meters |

Business Results

- ✅ Real-time Visibility: Engineers can monitor motor load from the office, reducing inspection time.

- ✅ Predictive Analysis: Historical data graphs allow for early detection of motor wear or abnormal load patterns.

- ✅ Cost Effective: Built on Open Source technologies (Node-RED, Vue.js, MySQL), significantly reducing licensing costs.

Expert Insight: “Using Node-RED as a middleware allowed us to rapidly prototype and deploy the Modbus communication logic. Combined with Vue.js, we delivered a ‘SCADA-like’ experience in a fraction of the time and cost of traditional industrial software.”

Ready to upgrade your factory? Contact us at: wisit.paewkratok@gmail.com