Digitalization of Batch Process in Rubber Industry

Problem Statement: In traditional rubber mixing, reliance on standalone PLCs often limits the complexity of recipe management and data storage. The client needed to upgrade a Banbury Mixer 75L to handle complex step sequences based on Time and Temperature, while ensuring 100% data traceability for quality assurance (QA).

The Challenge: The project required high-level interoperability. We had to centralize data from diverse legacy devices speaking different protocols (Ishida Scales, Delta Temperature Controllers, Ammeters) into a single control interface, all while maintaining millisecond-level stability for motor control.

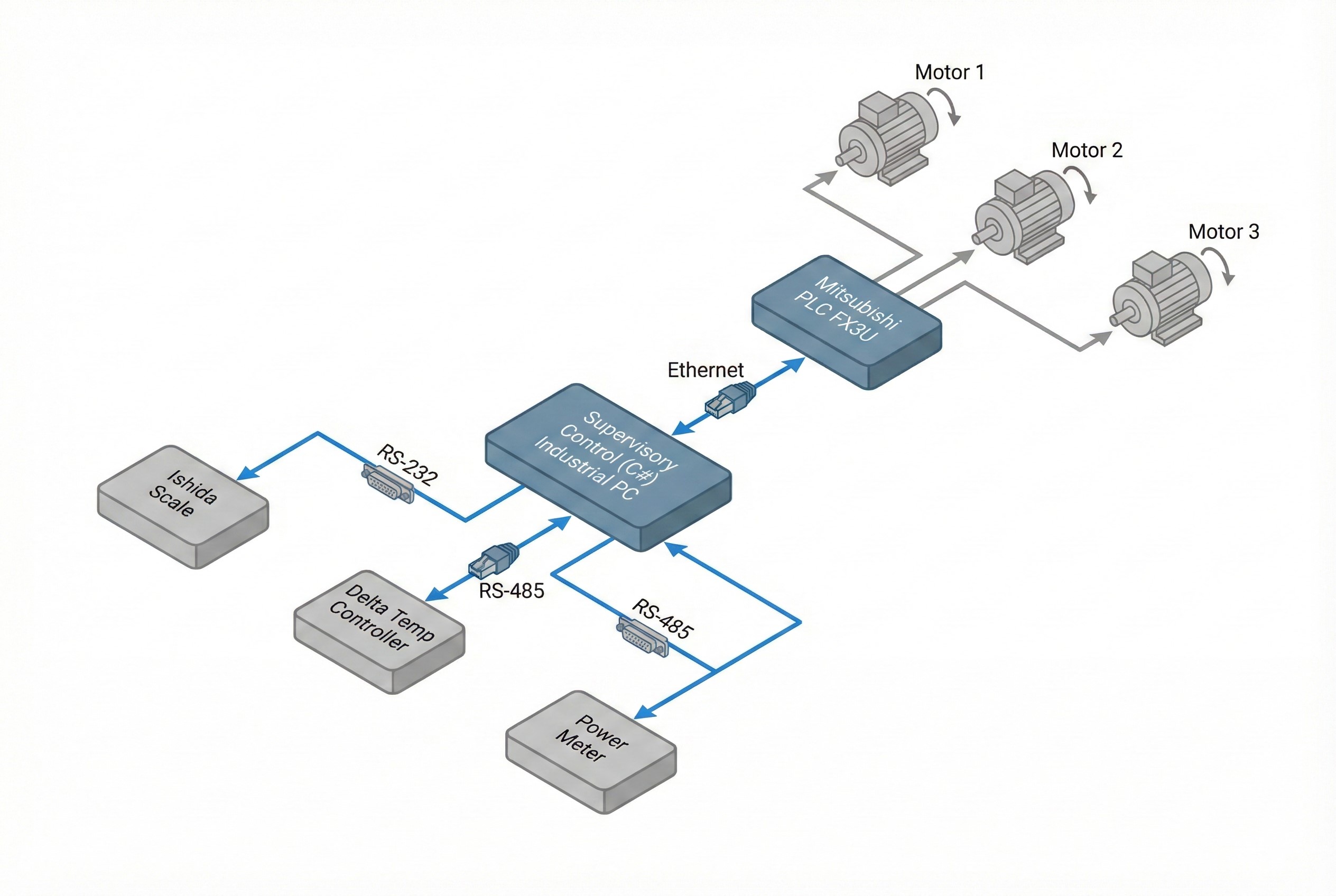

Our Solution: Hybrid PC-Based Supervisory Control

We moved beyond the traditional “PLC-only” approach by implementing a Hybrid Architecture.

- The Brain (PC): A custom C# application handles complex recipe logic, massive data logging, and the HMI.

- The Muscle (PLC): A Mitsubishi FX3U PLC handles critical I/O operations and safety interlocks.

Key Technologies Implemented

| Technology | Role in System |

|---|---|

| C# (.NET/WPF) | Supervisory control, Recipe Management, and Advanced UI/UX. |

| Mitsubishi FX3U | Real-time I/O control for motors and hydraulics. |

| Protocol Gateway | Unified RS-232, RS-485 (Modbus), and Ethernet into one system. |

| SQL Database | Storing batch history for claims and traceability. |

Business Results

- 100% Traceability: Detailed logs of temperature, current, and mixing time for every batch, ready for QA claims analysis.

- Hardware Agnostic: Successfully integrated Ishida Scales and Delta Controllers without replacing functional legacy hardware.

- Remote Monitoring: Decoupled architecture allowed managers to monitor production status from the office via LAN, separating the Operation from Monitoring.

Expert Insight: By offloading “Data Heavy” tasks to a PC and keeping “Action Heavy” tasks on the PLC, we bypass the memory limitations of standard PLCs, enabling unlimited recipe storage and complex reporting features.

Ready to upgrade your legacy machines? Contact us at: wisit.paewkratok@gmail.com