Auto Transfer Laser Mark System

Problem Statement: In a high-precision machining line, operators were manually transferring production data files from CNC machines to Laser Markers. This manual process, involving walking with USB drives or hand-keying serial numbers, created a bottleneck and introduced a high risk of “Human Error”—resulting in mislabeled parts and traceability issues.

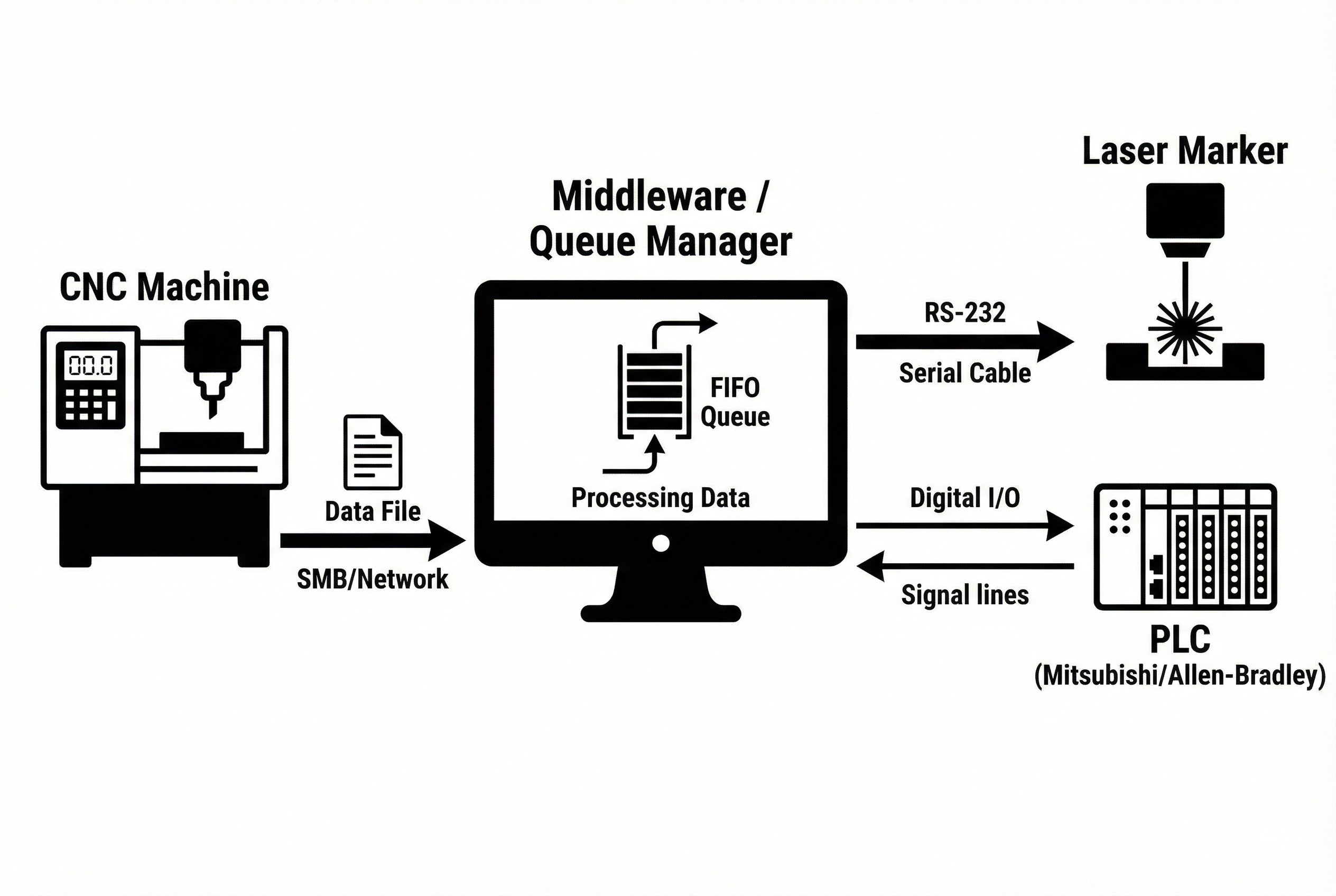

The Challenge: The core challenge was Cross-Platform Integration. We needed to bridge “Islands of Automation” that spoke different languages:

- CNC Machines (IT): Output raw data files via Network Drive/SMB.

- Laser Markers (OT): Require specific serial commands via RS-232.

- PLCs (Control): Manage production timing via Digital I/O triggers (Mitsubishi/Allen-Bradley).

Our Solution: The Middleware Integration

We developed a robust Middleware Application acting as a central data logistics hub. Instead of relying on human operators, the system automates the entire “Production Data Flow.”

Key Features

- Information Logistics (FIFO Queue): The system manages data like a conveyor belt. It queues production files in a First-In, First-Out (FIFO) order, ensuring the serial number printed matches the physical part arriving at the station.

- Digital Poka-yoke: By eliminating manual entry, we created a fail-safe process. The system performs a “Handshake” with the PLC to verify the exact trigger moment before sending data to print.

- Traffic Control Dashboard: A real-time Queue Grid View allows supervisors to monitor the backlog, re-prioritize urgent jobs, or clear errors without stopping the line.

Key Technologies Implemented

| Technology | Role in System |

|---|---|

| C# / .NET | Core middleware logic and UI for Queue Management. |

| SMB / Network Share | Fetching raw data files from CNC machines automatically. |

| RS-232 (Serial) | Direct communication protocol to control the Laser Marker. |

| PLC Integration | Handshaking with Mitsubishi/AB PLCs for precise timing. |

Business Results

- 100% Data Accuracy: Eliminated typing errors and mismatched serial numbers.

- Reduced Cycle Time: Removed the time wasted on manual file transfer and setup.

- Traceability Assurance: Every part is marked with the correct data derived directly from the CNC source.

Expert Insight: “The key to this project wasn’t just connecting cables; it was managing the ‘Information Logistics.’ Treating data packets with the same discipline as physical parts (FIFO) is what makes a Smart Factory truly reliable.”

Ready to automate your production data flow? Contact us at: wisit.paewkratok@gmail.com