3-in-1 Industrial Data Logger (Weight/Thickness/Length)

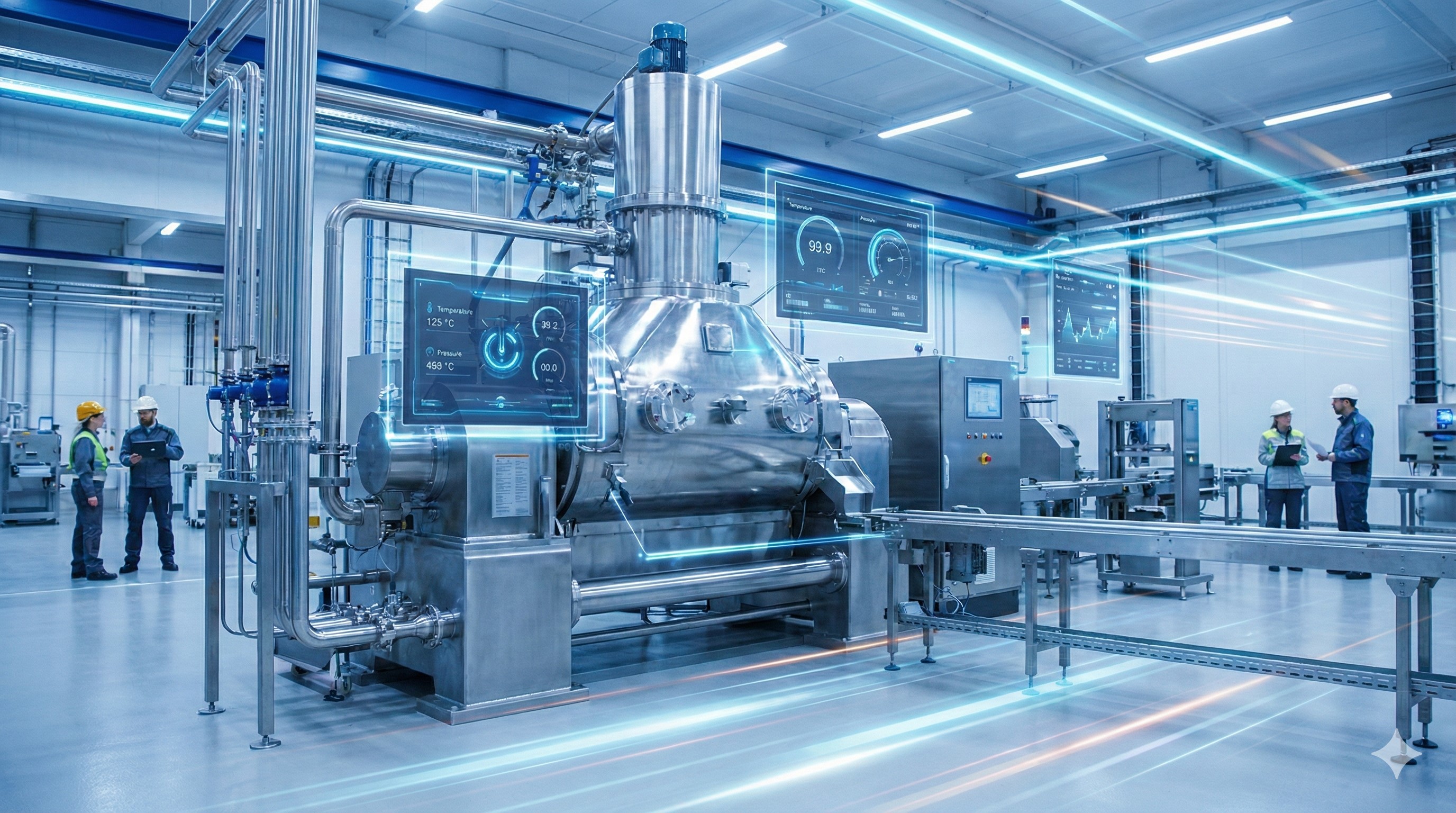

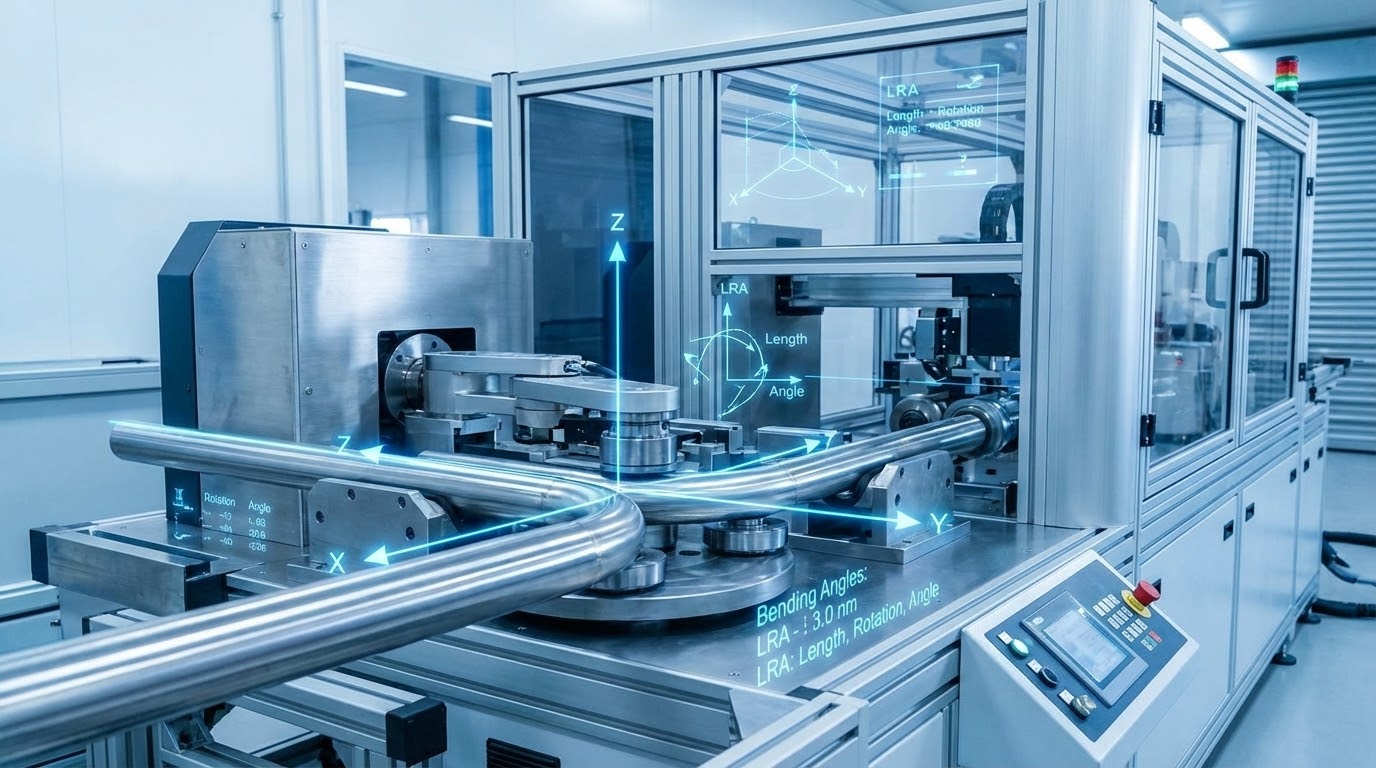

Digitalizing Quality Control Data Problem Statement: Manual data recording in high-speed manufacturing is prone to “Human Error” and creates “Data Silos.” At ETON INDUSTRY, operators had to manually write down critical parameters (Weight, Thickness, Length) for every finished product, leading to delayed reporting and inaccurate traceability. The Challenge: The system needed to interface directly with the existing machine’s PLC to capture data exactly when the process finishes, without disrupting the operator’s workflow. It also required a robust “Target Counter” to alert operators when a specific order quantity was met. ...